BT-12 Cryogenic Liquid Oxygen Tanks

Price 10000 USD ($)/ Unit

BT-12 Cryogenic Liquid Oxygen Tanks Specification

- Grade

- Industrial

- Processing

- Welded

- Tolerance

- 1%

- Condition

- NEW

- Dimension (L*W*H)

- 3500 x 1600 x 2100 mm

- Capacity

- 12000 Liters

- Application

- Storage of liquid oxygen at cryogenic temperatures

- Inner Vessel Thickness

- 8 mm

- Working Pressure

- 8-17 Bar

- Material

- Stainless Steel 304/316

- Weight (Empty)

- 4500 kg

- Mounted

- Horizontal

- Corrosion Resistance

- Yes

- Insulation Type

- Vacuum Super Insulation

- Test Pressure

- 22.5 Bar

- Design Temperature

- -196°C

- Outer Vessel Thickness

- 5 mm

About BT-12 Cryogenic Liquid Oxygen Tanks

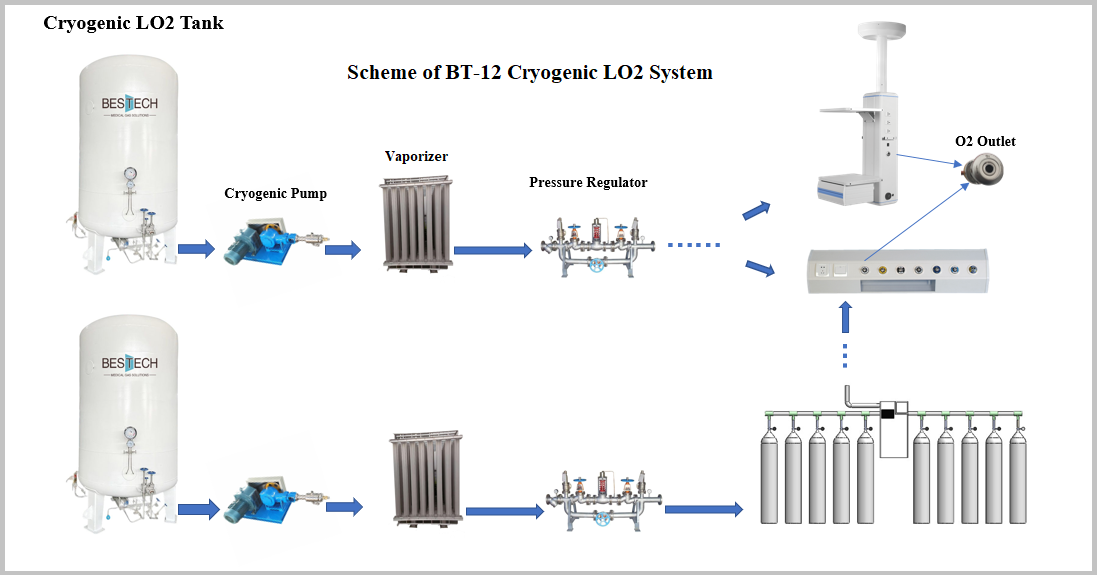

Features of BT-12 Cryogenic LO2 Tanki14

1. Adiabatic performance:

Thermal insulation material selection of pearlite sand filling sandwich and vacuum, superb technology, unique filling process, quality assurance commitment, to achieve the best adiabatic effect. The surface anti-corrosion coating adopts sand blasting, rust removal, purging, spraying and other processes, and at the same time adopts two-component quick curing liquid coating.

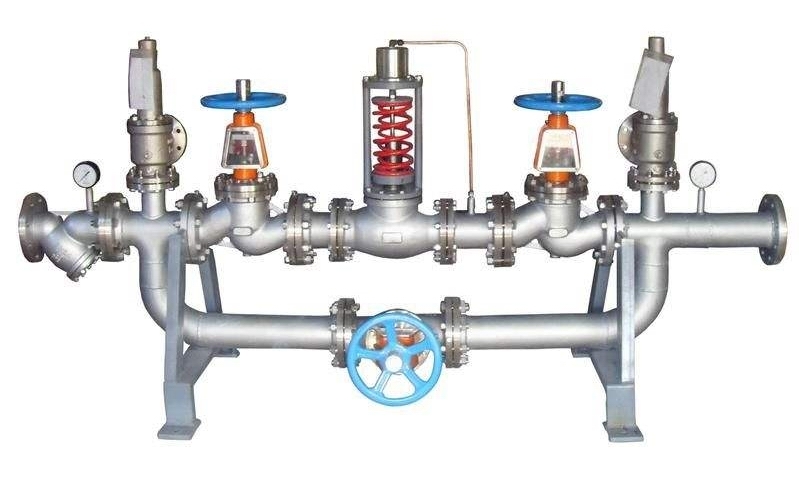

2. Safety technical performance:

The storage tank adopts "combination and safety system valve", which USES two groups of safety valves to work at the same time. One side can be closed when the safety valve is regularly checked, and the other side can continue to work to ensure the safe operation of the storage tank.

3. Operating system:

Pressure gauge, differential pressure type liquid level meter and liquid level comparison table are set on the upper part of the container in the storage tank, which can keep track of the storage amount and pressure change of the container at any time, and facilitate the operation during filling and discharging.

4. Detection system:

Special vacuum detection, vacuum gauge and vacuum valve are set at the lower part of the storage tank, which can test the interlayer vacuum degree regularly or at any time with a vacuum meter to ensure the safe operation of the storage tank.

Superior Material and Craftsmanship

Constructed from premium Stainless Steel 304/316, the BT-12 Cryogenic Liquid Oxygen Tank provides excellent resistance to corrosion, even in challenging environments. Its welded assembly ensures long-lasting strength and leak-proof operation. The vacuum super insulation technology preserves ultra-low temperatures, minimizing product loss and energy consumption.

Versatile Industrial Applications

With a capacity of 12,000 liters and design features tailored for stability and safety, this tank is ideal for storing liquid oxygen in various industrial sectors such as manufacturing, healthcare, and research facilities. Featuring strict tolerances of 1%, it guarantees volume accuracy and operational safety.

FAQ's of BT-12 Cryogenic Liquid Oxygen Tanks:

Q: How is the BT-12 Cryogenic Liquid Oxygen Tank insulated for maintaining cryogenic temperatures?

A: The BT-12 tank utilizes vacuum super insulation, which creates a near-vacuum space between the inner and outer vessels. This advanced insulation method drastically reduces heat transfer, ensuring the stored liquid oxygen remains at cryogenic temperatures as low as -196C.Q: What steps are involved in the storage process of liquid oxygen using this tank?

A: Liquid oxygen is carefully filled into the insulated inner vessel, and the tank's welded construction ensures leak-proof containment. Regular maintenance includes pressure monitoring and visual inspections to ensure optimal and safe storage.Q: When should this cryogenic tank be chosen for industrial use?

A: This tank is best suited for scenarios requiring large-volume, long-term storage of liquid oxygen, especially where temperature retention and safety are paramount. Typical use cases include hospitals, manufacturing plants, and research laboratories.Q: Where can the BT-12 tank be installed?

A: The tank's horizontal mounting and robust construction allow for installation in a variety of industrial locations, whether indoors or outdoors, provided there is adequate space to accommodate its dimensions (3500 x 1600 x 2100 mm) and allow safe handling.Q: What are the primary benefits of using this model for cryogenic liquid oxygen storage?

A: Key advantages include superior thermal insulation, reliable corrosion resistance, precision construction with 1% tolerance, and high capacity, ensuring safety, efficiency, and minimized oxygen loss during storage.Q: How does the tank ensure safety during operation?

A: The tank is engineered with a test pressure of up to 22.5 Bar, far exceeding its working range of 8-17 Bar, which provides a significant safety margin. The sturdy welded structure and corrosion-resistant material further enhance operational safety for users.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese